Interko achieves breakthrough with energy consumption of new ripening room fan

Interko has raised the bar higher in its commitment to developing advanced ripening solutions for the global fresh fruit and vegetable industry.

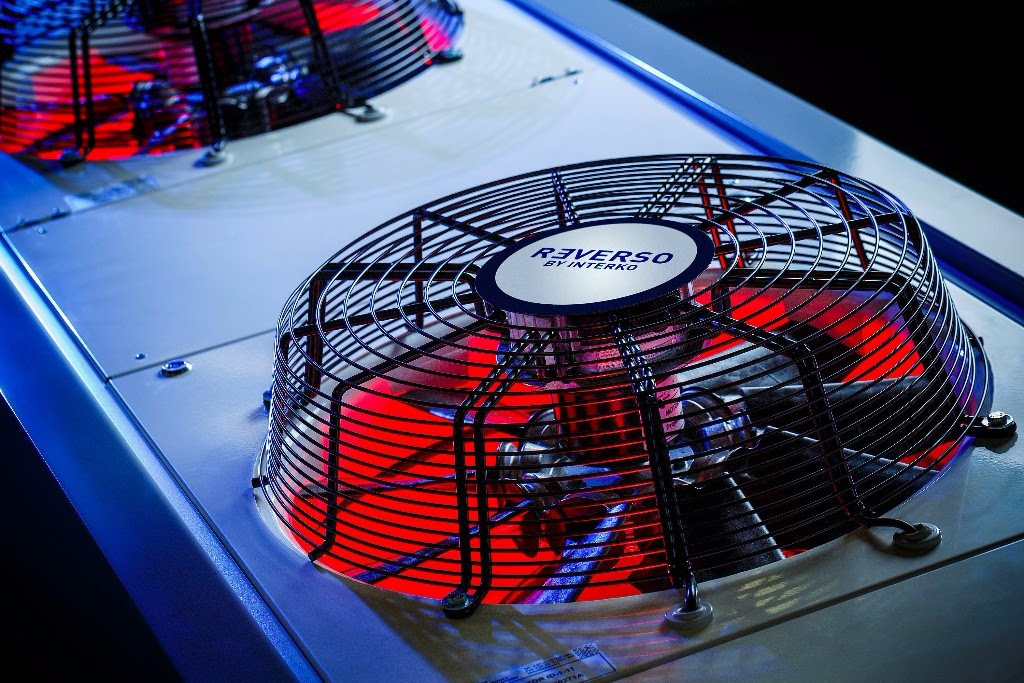

The Dutch manufacturer has achieved a breakthrough with the energy efficiency rating of its new range of reversible ripening room fans, which are now supplied under the brand name RƎVERSO.

“Interko is the first company to manufacture a ripening room fan that achieves an energy consumption level below 100 watts per pallet at full airflow, which is fantastically low,” reveals Chris Maat, the managing partner of Interko.

“This development will translate into considerable cost savings for our customers. Reducing energy usage and costs as much as possible is critical for many of our clients today. They also want greater flexibility, and quality is vital, of course.

“That’s why we are constantly innovating,” Chris continues. “Client satisfaction is of paramount importance to Interko. We’re committed to developing bespoke solutions that make for extremely energy-efficient and cost-effective fruit ripening rooms to suit customers both large and small.”

The RƎVERSO reversible fan range provides efficient air movement technology and full user-controllability within a ripening room. The fans can be controlled simply and individually, meaning they can be switched off in any unloaded bays at any given stage.

The fans can also be linked to the fully-integrated and unique Interko Smart ripening control system. This allows for precision ripening and monitoring of the ripening process to a degree that has not previously been possible.

Interko invites produce professionals to learn more about the RƎVERSO fan range at the world’s largest fresh fruit and vegetable trade show, Fruit Logistica 2017. The fair takes place in Berlin, Germany, on 8-10 February. Interko will exhibit in Hall 1.2, B-11.

“We welcome visitors to come and meet our team to discover more about the tailor-made ripening solutions and heat exchangers we offer,” Chris says.

Record results

Every day 4 million boxes of fruit are ripened in Interko rooms worldwide. The business is expanding significantly and after closing 2016 with record results, Chris says the company is looking forward to a promising future.

“Thanks to the increasingly broad-based geographical distribution of our business, we have delivered our strongest performance to date,” Chris explains.

“During the last 12 months we have built over 200 ripening rooms across the world; with orders coming from Europe, South America, Asia and beyond.”

This year Interko is eager to build upon its heritage as a leading provider of fresh fruit ripening systems. At the same time the company continues to provide its clients with premium service and after-sales support.

“A service-oriented approach has been the hallmark of our business since Interko began some 40 years ago, and, driven by our desire to provide our customers with distinctive ripening innovation, we remain as committed as ever to our long-term partnerships,” Chris says.

Meet Interko at Fruit Logistica!

Fruit Logistica

Hall 1.2, Stand B-11

8-10 February 2017

Berlin, Germany