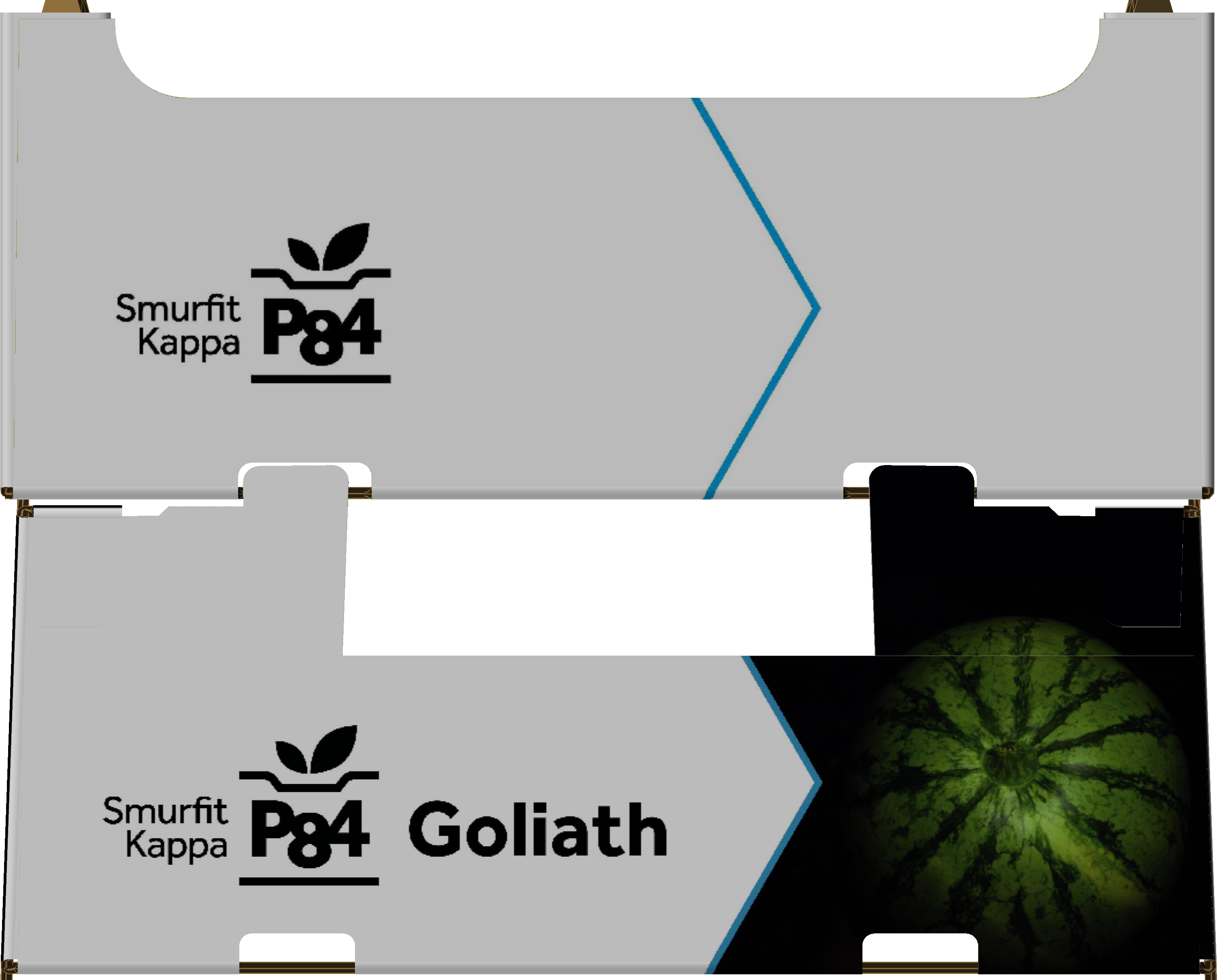

Goliath; the success of the new watermelon box with 1 million units sold

The watermelon is a fruit with very specific characteristics that requires packaging designed to absorb any potential damage caused by its weight. The packaging must be stackable, and suitable for both long-distance transport and display at the point of sale. Smurfit Kappa has managed to combine these features in its latest revolutionary product, Goliath, a corrugated cardboard packaging solution for the fruit and vegetable sector. One million units have already been manufactured with 100% satisfaction from the customers who have tried them (zero claims have been filed for collapsed boxes). In this interview, Enrique Guillén, Regional Manager of Smurfit Kappa Alicante and Almeria, two plants 100% dedicated to the design and manufacture of packaging solutions for the agricultural industry, talks to us about this new box and the company’s commitment to innovation in this market.

How did Goliath come about?

Innovation is one of our main pillars. So when our customers in the sector asked us for an efficient solution, developed specifically to transport and store watermelons, meeting a set of criteria that would ensure the products ‘arrival at the point of sale in perfect condition, our designers got to work to create an innovative package that would solve the producers’ dilemma at its source. That was the beginning of Goliath, a product developed at our Agri Experience Centre in Alicante, Europe’s unique centre devoted 100% to agricultural research, development and innovation, where efficient (and) sustainable designs are conceived.

What are its main features?

Thanks to its conical shape, Goliath is able to absorb any impact caused by the weight of the fruit. Its internal anchors allow for perfect stacking, thus improving loading efficiency; it optimises ventilation and preservation of the fruit; it is recyclable, renewable, and biodegradable to minimise the ecological footprint of our customers; and it strengthens the customer’s brand image by supporting any type of printing. Originally designed for watermelons, it is now being used successfully to package other fruit, such as melons, citrus fruit, and even bananas.

How has Goliath evolved?

Smurfit Kappa’s designers developed a new version of this solution, the so-called Goliath 2.0, which—thanks to its redesigned anchors—allows Goliath to be stacked according to different market formats, a development much appreciated by retailers, while also providing better ventilation. The advantages of this latest solution are being presented to new and prospective customers through webinars led by the Agri Experience Centre (AEC@smurfitkappa.com).

Goliath is also suitable for both long-distance transport and display at the point of sale.

That’s right. Thanks to its cone-shaped design that can support 20 kg. of product, Goliath is the ideal solution for exporting fruit, since—in addition to all the aforementioned advantages—it streamlines distribution, minimises unoccupied warehouse space, eliminates collapsed box claims, and reduces fall incidents to virtually zero, a very important point considering the unique characteristics of the watermelon. It also reinforces food safety and hygiene because cardboard transmits less bacterial contamination than other non-biodegradable material. Moreover, all of our agricultural plants in the Iberian Peninsula are certified with the BRC Global Standard for Food Safety.

Goliath’s innovative design ensures fruit arrives at its final destination in perfect condition, an aspect much appreciated by our agricultural customers, especially brand owners who use packaging to reinforce their designation of origin, brand, and values by printing images, logos, and text on the boxes, a distinctive element that drives consumption.

About Smurfit Kappa

Smurfit Kappa, a company that trades on the FTSE 100, is one of the leading suppliers of paper packaging solutions in the world, with roughly 46,000 employees at approximately 350 production centres in 35 countries and revenues of EUR 9 billion in 2019. We are present in 23 European countries and 12 countries across the Americas. We are the only large-scale pan-regional operator in Latin America.

Our proactive team consistently applies its experience and expertise, backed by our structure, to provide our clientele with new opportunities. We collaborate with forward-looking customers through the exchange of superior product knowledge, market expertise, and an understanding of packaging trends to ensure business success in their markets. We have a portfolio of unprecedented paper packaging solutions that is constantly updated with our market-leading innovations. This is reinforced by the benefits of our integration, with optimum paper design, logistics, prompt service, and packaging plants whose raw materials are supplied almost entirely by our own paper mills. Our products, which are 100% renewable, recyclable, and sustainably produced, help improve our customers’ environmental footprint.

Visit our microsite & web www.openthefuture.es / www.smurfitkappa.es