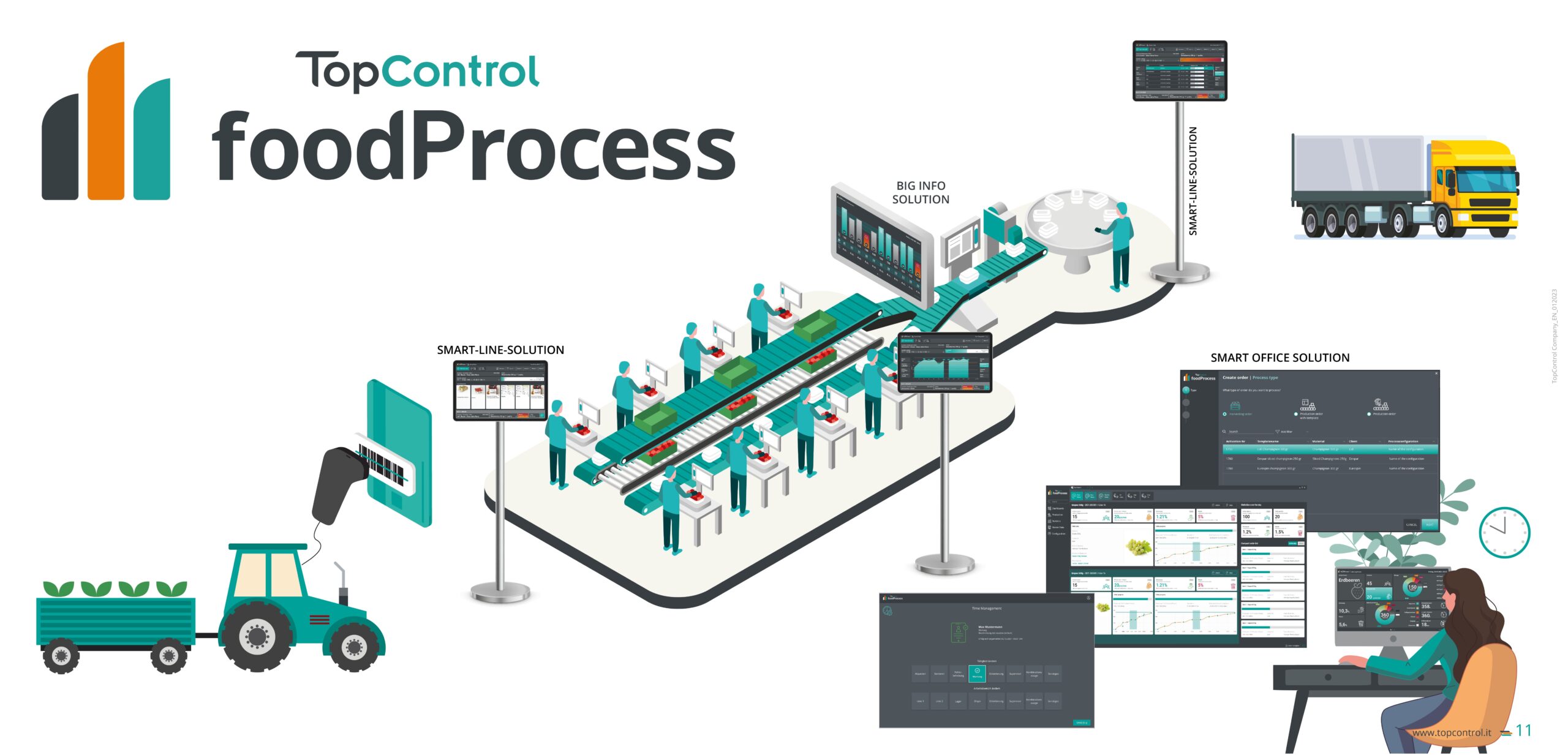

foodProcess – Foodpacking: intuitive, well thought-out, everything in view

At the touch of a button, foodProcess determines weight information with giveaway, activity and performance data, sales forecasts and much more in user-defined reports. All data is stored in real time on a local server and can be accessed at any time via intuitive dashboards.

Paperwork is a thing of the past. foodProcess optimises your internal processes through data automation. By connecting to your ERP system, your orders are automatically transferred and can be sent to your lines on the production floor.

Order Processing

- The machines of your packaging line are set automatically. The necessary order-specific parameters are automatically set when the order is sent to the various machines on your line. This significantly reduces set-up times.

- Order data such as product to be processed, packaging material, quantity to be produced, weight limits, label preview and much more are sent directly to the line. Weighing systems are already set appropriately for this order. The error rate is drastically reduced.

- Packaging, weight and quantity data can be intuitively viewed by your staff at the line terminal at any time.

Production Monitoring

During the processing of the packaging or repackaging order, the current status is visible at all times. Colour changes in the dashboard indicate whether the expected productivity has been achieved, the delivery date has been met and the giveaway complies with the specifications. It is thus possible at any time to make any necessary adjustments, such as increasing the number of staff working on the line or checking the quality of the goods, in good time.

Traceability

The complete traceability of goods and packaging materials is guaranteed via foodProcess. Incoming goods are registered and this stored data is transferred to each production and storage step. These materials are thus clearly assigned to the order and identifiable.

Messageboard

Important information for the staff in the packing hall can be sent to the hall as a message via foodprocess and displayed there on the terminals and BigScreens.

Data Management

Articles, users, process configurations and orders are created and managed clearly and intuitively in foodProcess. This means that you have all your data in one place.

Recording & Evaluation

foodProcess collects all production data for you so that it can subsequently be evaluated at order, line or user level with the corresponding KPIs such as giveaway, productivity and much more. So at the end of the day you know how much profit you are really making.

Get started with foodProcess and optimise your production.

Highlights:

Real-time monitoring & control of your packaging lines

Clear production monitoring

Intuitive process configuration

Easy traceability

For more informations:

TopControl

sales@topcontrol.it

Tel. +39 0471 319 999

www.topcontrol.it