Climate targets spark innovation to meet cooling demand

- Logistics

- Technology

- EU

- GCCA

- Global Cold Chain Alliance

- 2030

- Climate Targets

- Cooling Requirements

- Innovation

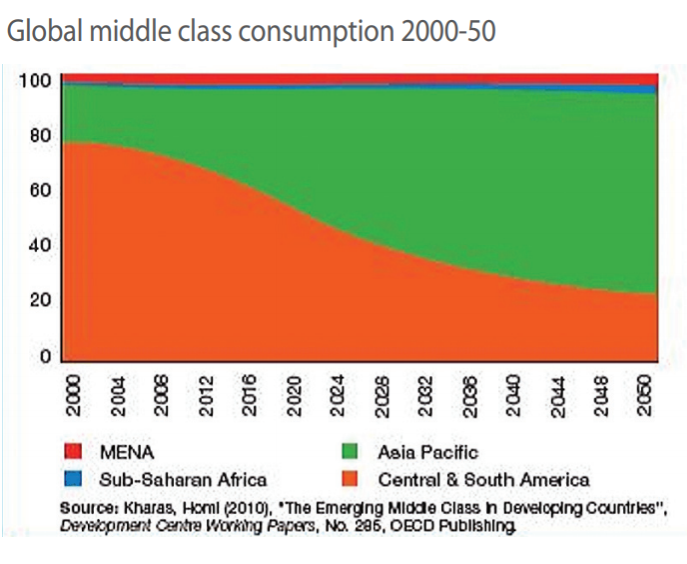

A major increase in cooling demand is colliding with the European Union’s ambitious climate and energy strategy which sets strict targets to achieve by 2030. Among them are the need to cut greenhouse gas emissions by at least 40% on 1990 levels and increase energy efficiency by at least 27%.

Moreover, the EU is entering a new phase in fluorinated gases (F-gases) regulation in which the availability of one group of them, hydrofluorocarbons (HFCs), will be cut 79% by 2030.

Current uses of HFCs include as a refrigerant in cooling systems, but they are known to act as a greenhouse gas, contributing to global warming. The overall package of EU measures will force the cold chain to focus on the issue of emissions and develop alternatives with less environmental impact.

When it comes to refrigerants, ammonia is one such alternative.

“The use of ammonia (NH3) – a naturally occurring refrigerant with zero ozone depletion and global warming potential – offers a wide range of benefits. It is future proof as it will not be phased out by new legislation and offers higher efficiencies than HFCs,” said Aiden Perks, business development manager (South East UK) for Star Refrigeration.

The company has developed low charge ammonia packaged systems which require only a fraction of the refrigerant charge associated with traditional refrigeration systems. The systems are not only more efficient than HFC options, they also have a lower life cycle cost, pose zero risk to employees and the new units cost less than conventional ammonia installations.

Another innovation in the cold chain is the use of liquid air or liquid nitrogen. Dearman Engine Company – which is developing novel zero-emission technology to provide cooling and power – is working on an innovative novel piston engine powered by liquid air or liquid nitrogen. The only exhaust is cold air.

Liquid air or nitrogen is boiled to provide a high pressure gas that is used to fuel transportation vehicles. During the process, cooling is created which is harnessed to cool the load of the vehicle. The process of liquefaction is a very trusted one, said Dearman’s global ambassador Tim Fox. It is over 100 years old and present in every industrialised nation. Moreover, the distribution and storage technology and infrastructure are mature.

The use of the Dearman technology offers abundant benefits – zero-emission at the point of use, reduced noise, lower fuel costs and reduced CO2 emissions, to name but a few. On-road commercial trials will begin shortly.

So although it looks like a lot is hitting the cold chain sector – a huge increase in demand and many new regulations – there are also many innovative solutions helping propel the sector towards a bright future.

Top image: European Commission: 2030 Energy Strategy