FarmFresh packaging sustainability attributes showcased at Fruit Logistica Berlin 2023

FarmFresh packaging solutions, developed by Termotécnica for the agribusiness market, will be on full display at Fruit Logistica Berlin 2023, an event that brings together the global distribution chain of fresh fruits and products, held from February 8 to 10, in the German capital. FarmFresh conservers will be at the Brazil Pavilion – corridor 23, stands B1 to B21 – coordinated by Abrafrutas (Brazilian Association of Exporters of Fruit and Derivatives).

In just five years, more than 1.2 million FarmFresh conservers have been used to export over 5,000 tons of premium Brazilian fruits such as mango, grape, lemon and lime, pitaya, fig, papaya, guava, passion fruit, lychee, atemoya, to countries across Europe, such as France, Spain, England, Austria, as well as to the Middle East, Russia, China and Canada. “By extending shelf-life, maintaining a stable temperature and being very light, our packaging also contribute to sustainability aspects such as reducing losses and waste in the distribution chain in addition to lowering CO2 emissions into the atmosphere, as well as being 100% recyclable”, states Termotécnica’s Managing Director, Nivaldo Fernandes de Oliveira.

Post-consumer packaging recycling cases in France and England

An essential aspect to serve the foreign market, mainly in Europe, is the concern with sustainability. Issues such as the circular economy (reverse logistics and post-consumer packaging recycling), food waste reduction throughout the chain and lower CO2 emissions in transport are increasingly important.

Since it began working with fruit exporters, Termotécnica has been a member of the Global Packaging Alliance, a global partnership for packaging recycling. And recently became one of the partner suppliers of Fermac Cargo, now part of the Corporate SAF Programme – Sustainable Aviation Fuel – of Air France KLM Martinair Cargo – a milestone that symbolizes the pursuit for more sustainable aviation. Through SAF there has been a CO2 reduction of around 102,070 kg on the three main routes used in the export of Brazilian fruits to Europe in the partnership between Fermac and Air France KLM Martinair Cargo.

One of the mango shipments from the Brazilian producer Happy Fruits processed by the European fruit importer and distributor Capexo on board Air France’s “eco-friendly” aircraft was sent to Paris in FarmFresh conservers. Manufactured in EPS (better known as styrofoam*), FarmFresh solutions weigh 60% less than corrugated boxes, reducing air freight costs by up to 6%, generating significant savings throughout the chain and therefore lowering CO2 emissions on the planet.

But what to do with conservers after their use? Committed to closing the entire reverse logistics cycle, Termotécnica partnered with the recycler ECO 2PR, from France, to collect the packaging from these shipments. “The world and the markets are ever more demanding with regard to the environmental footprint of companies, and we’re committed to this agenda by presenting solutions that are in-line with these demands”, says Termotécnica’s President, Albano Schmidt.

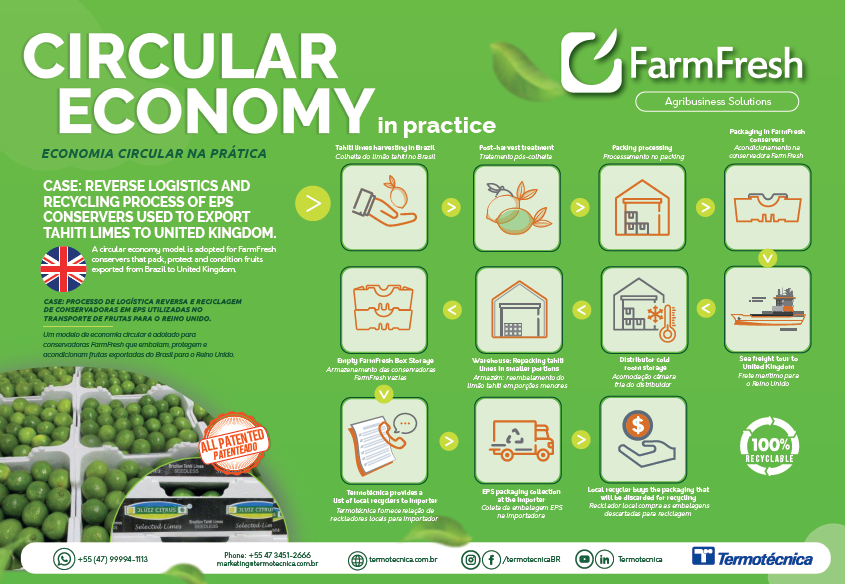

Another success case of this reverse logistics and recycling process is Tahiti Lime export from Brazil to the United Kingdom. The circular economy model is already adopted for FarmFresh conservers where the fruits pass through the packaging and conditioning process and are shipped via sea freight to the United Kingdom. Termotécnica supplies the importer with a list of local recyclers. They, in turn, negotiate the sale to one of these recyclers who collect post-consumer packaging at the importer and process its recycling, that is, an example of the circular economy happening in practice.

In terms of sustainability, FarmFresh conserver boxes contribute on three fronts:

1) In post-consumer recycling, as EPS is a material that can be 100% recycled and transformed into raw material for other applications, such as vases, skirting boards and moldings.

2) Increase shelf-life of fresh products by up to 30%, which helps reduce losses and waste in the distribution and consumption chain, in-line with the SAVE FOOD Initiative from the FAO/UN.

3) Contribute towards lowering the carbon footprint, with the reduction of CO2 equivalent emissions in transport due to the solutions’ lighter weight, which reduces fuel consumption. In a study conducted by Green Domus, comparing GHG emissions to transport a cargo of mango between Petrolina (PE) and Lisbon (POR), FarmFresh EPS packaging and pallets accounted for 5.44% less emissions than corrugated boxes.

The difference amounted to 2,492.39 tons, which is equivalent to the emissions of 88,226 people/day.

FarmFresh provides effective real gains for fruit exports

Thinking about the quality of export fruits, from the field to the consumer’s table, FarmFresh solutions have been a differential that adds a great deal of value to the entire chain. Nivaldo de Oliveira reinforces that “packaging is an important vehicle to position and communicate these benefits as well as add value. All the conservation technology and design of our FarmFresh EPS solutions allow our customers to communicate these quality differentials of Brazilian fruits to the international markets”.

FarmFresh EPS packaging solutions provide real gains and increased competitiveness for export businesses:

- Significant loss reduction in long-distance shipments.

- Temperature conservation, without breaking the cold chain, and less fruit dehydration.

- Lower air freight costs, with fewer kilos per pallet, generating savings in total freight costs.

- Valuing the fruit at the point of sale, with market share gains.

* Styrofoam is a registered trademark of third parties.