Smart Ripe Trolley, Ilip releases an innovative system for controlling the ripening of avocados in the room

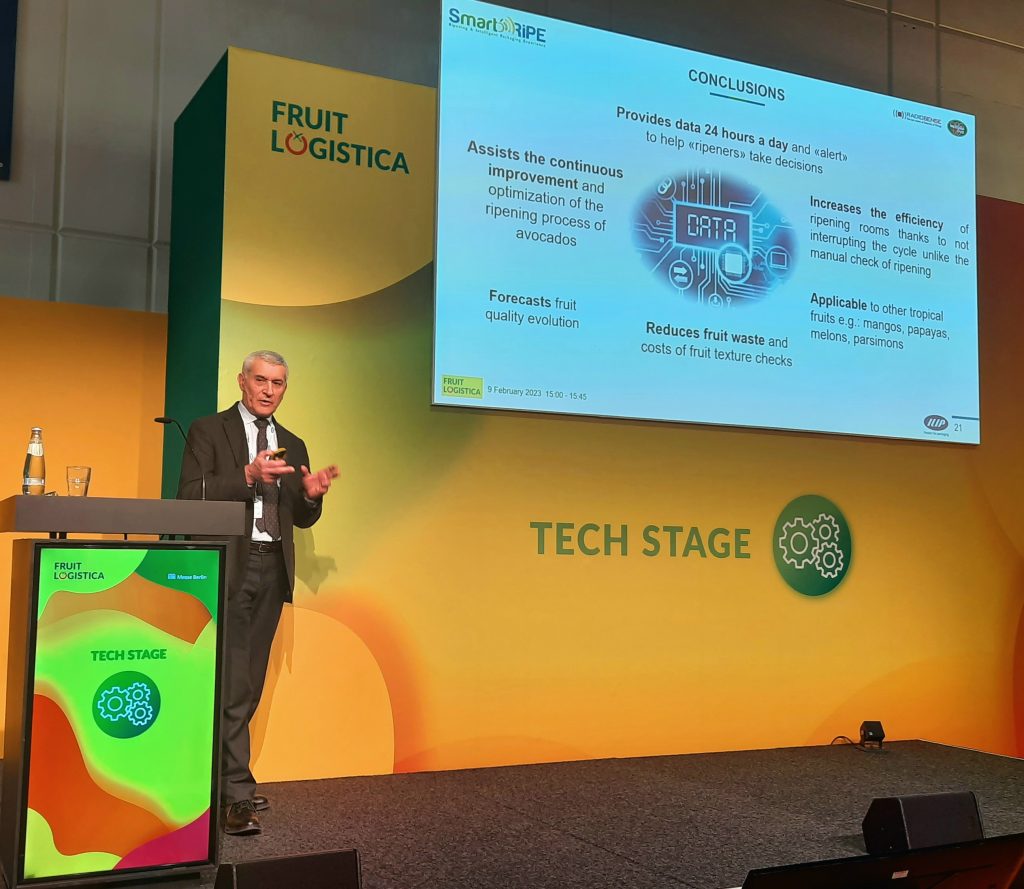

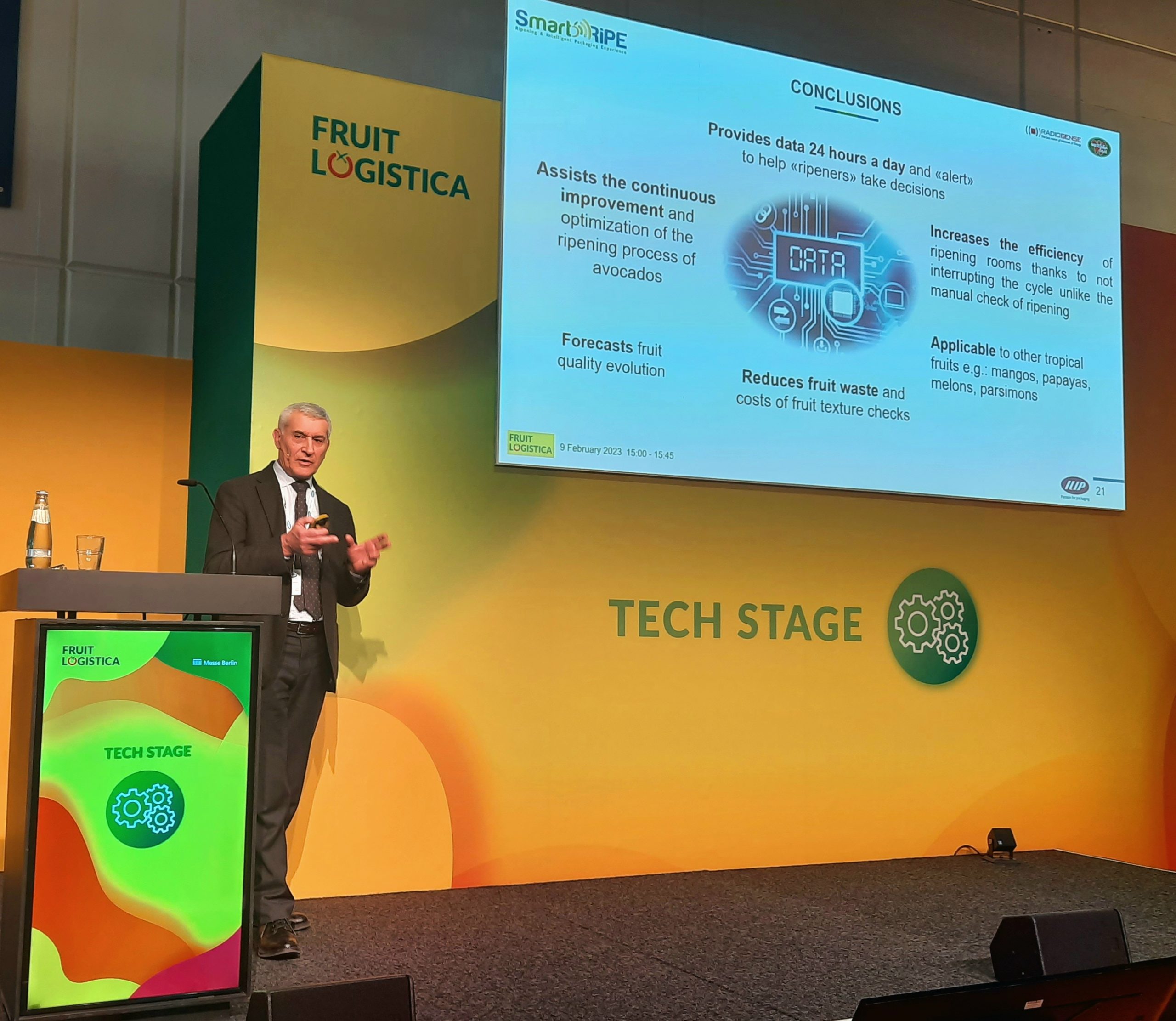

Berlin, February 2023 – The monitoring of the degree of ripeness of tropical fruit is one of the key aspects in managing operations at the packing houses of importers to offer the market fruit at the desired quality and ripeness. ILIP has dedicated its intervention entitled “Smart Ripe Trolley: monitoring the ripening of tropical fruits with RFID sensors” at the Tech Stage forum organised by the Berlin trade fair as part of Fruit Logistica, precisely to this topic that regards exporters of tropical or out-of-season fruit.

The company addressed a public of international operators to unveil an important innovation in the field of smart packaging: the Smart Ripe Trolley, an innovative IoT (Intelligence of Things) system that monitors the ripening process of tropical fruits (in particular avocados) for industrial uses, whose function is based on RFID tags and sensors installed on a trolley. The results of the control are shown in real time on a digital platform. This new solution is an evolution of the Smart Ripe (developed by ILIP in 2019), which, differently to the Smart Ripe Trolley, has been designed for the retail sector, to determine the degree of ripeness of the avocado on the shelves and applies to the individual packaging using the RFID tag sensor integrated into the pack.

The Smart Ripe Trolley project is the result of collaboration between the ILIP Research and Development Department and the Innovation Department of Westfalia Fruit Group, a multinational specialised in the production and sale of avocado. “After the first presentation at the 2019 Fruit Logistica Tech Stage of the Smart Ripe in trays for the individual fruit for the retail sector” – Luigi Garavaglia, ILIP’s R&D Manager says- “we were contacted by Westfalia Fruit, who described their need to assess the progress of ripening of avocados in the ripening rooms, which are a sealed environment containing ethylene, without invasive tests on sample of the fruit and without opening the room, because doing so each time interrupts the treatment and modifies the atmosphere, requiring subsequent restoring of parameters”.

Thus began research with Radio6ense, which, at the end of the design phase, led to the development of a trolley with 4 shelves, each of which able to hold 32 fruits, each in its own nest, in which 3 RFID sensors are positioned. The tag RFID sensors detect changes in certain dielectric parameters of the fruit pulp associated with ripening, which they then transmit to the RFID reader installed on the trolley.

To take the readings in wireless mode, ILIP has collaborated with Radiosense (which analyses wireless data) to develop neuron processing software: the trolley holding 128 avocados is wirelessly connected to a remote IoT computational platform, namely neuron-type software with artificial intelligence. The Smart Ripe Diagnostics software yields interactive feedback, generating an automatic alert in the event of detections outside parameters, thereby allowing the operator to intervene on the ripening software. The correction will soon become automatic, thanks to direct interaction between the neuronal software and the management software.

The first tests on avocado (Hass variety) in a room with ethylene were started by ILIP with the partner Westfalia Fruit back in 2020 and are still ongoing. “The Smart Ripe Trolley, patented by ILIP, has been designed for fruit and vegetable operators and, in particular, for importers of tropical fruit and manufacturers of climate and ripening rooms with ethylene” – Luigi Garavaglia concludes – “and satisfies the need to estimate ripening without generating inefficiencies due to the alteration of the protected environment inside the room each time it is opened and product waste through daily invasive tests. This solution allows for the distribution to the market of ready-to-eat fruit, in respect of the protocols of modern organised distribution and guaranteeing constant quality standards”.